Floor heating welded wire mesh / Geothermal Mesh

The floor heating mesh called Geothermal Mesh,Ground heating mesh panel, the special floor heating mesh panel, welded steel wire mesh panel which is made of black steel wire...

PRODUCT DESCRIPTION

Geothermal Mesh Introduction

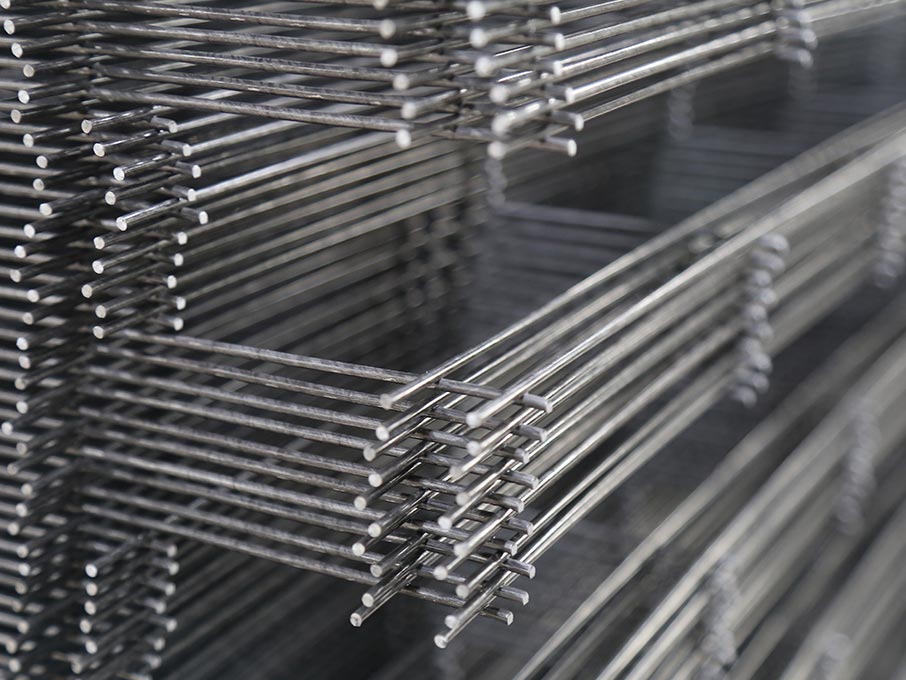

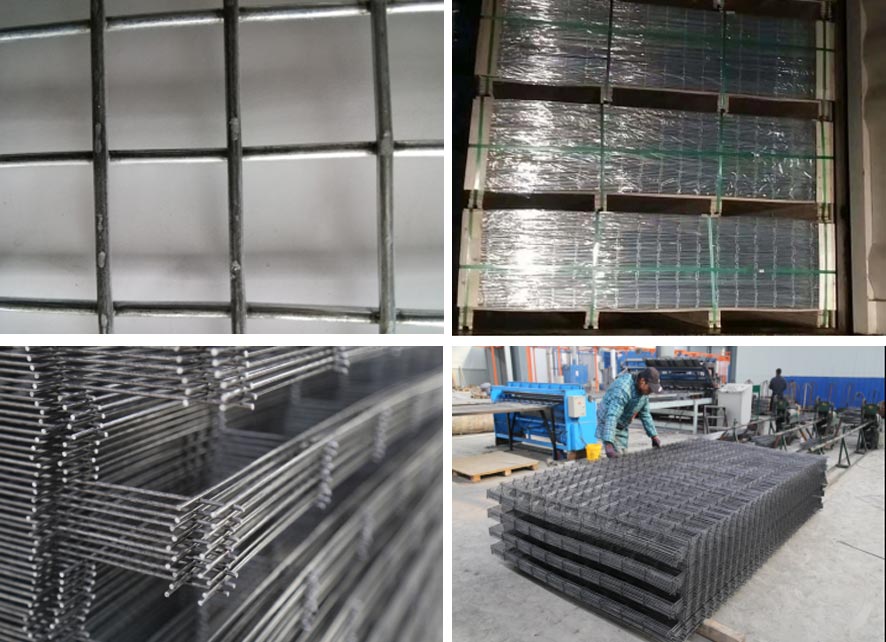

The floor heating mesh called Geothermal Mesh, Ground heating mesh panel, the special floor heating mesh panel, welded steel wire mesh panel which is made of black steel wire or redrawing wire.

Effect: Enhancing the whole strength of heat insulation palte; Installation eaysily; Fixed heating tube.

Specification

The wire diameter of floor heating mesh is from 1.5mm-4mm.

The mesh size: 5x5cm, 10 x 10cm, 5x10cm, 6 x 6cm

Normally used the floor heating mesh specification is wire diameter: 2mm, mesh size 10cm x 10cm, width: 1m, length: 2m

HS code: 73143100

Characteristic of floor heating mesh panel

1. mesh surface flat and smooth

2. mesh size even

3. tranportion easily

Advantage of floor heating welded wire mesh

1. easy to install the pipe, shorten consturction time, to be fixed the pipe.

2. can enhance the bearing capacity of the roof, avoid the ground crack, crack, collapse and other adverse phenomena.

3. wire mesh heat conduction performance is very good, can promote the uniform heat dissipation.

4. the most important point is thermal insulation and crack prevention, steel wire mesh in the construction project is a kind of thermal insulation and crack prevention material, the construction effect is very good, has been the trust of the construction industry.

The specificaion of Floor heating mesh

| WxL | Wire diameter (MM) | Mesh (CM) | Per Piece weight (KG) |

| 1M×2M | 2.00 | 10×10 | 1.06 |

| 1M×2M | 2.00 | 15×15 | 0.67 |

| 1M×2M | 2.00 | 20×20 | 0.56 |

| 1M×2M | 2.50 | 10×10 | 1.65 |

| 1M×2M | 2.50 | 15×15 | 1.04 |

| 1M×2M | 2.50 | 20×20 | 0.88 |

| 1M×2M | 3.00 | 10×10 | 2.38 |

| 1M×2M | 3.00 | 15×15 | 1.5 |

| 1M×2M | 3.00 | 20×20 | 1.27 |

Geothermal Mesh Application Areas

Geothermal Heating System

Concrete Reinforcement: Using geothermal mesh in the concrete foundation layer of geothermal heating system can significantly improve the crack resistance and structural strength of concrete. This mesh material enhances the overall stability of concrete through evenly distributed steel wire mesh, ensuring that geothermal pipes will not deform or damage during long-term use, thereby extending the service life of the system.

Geothermal Heating Pipeline

Structural Enhancement: Embedding geothermal mesh in the concrete jacket of geothermal heating pipes can effectively enhance the structural strength of the pipes. Its high-strength steel wire can effectively withstand high loads and pressures, prevent cracks and deformation caused by the expansion and contraction of the pipes in the geothermal environment, and improve the safety and reliability of the system.

Geothermal Energy Recovery System

Heat Exchange Efficiency Improvement: Applying geothermal mesh in the concrete structure of the geothermal energy recovery system helps to optimize the heat exchange process. By enhancing the strength and stability of concrete, the efficient operation of the heat exchanger is ensured, the energy utilization efficiency of the entire geothermal system is improved, and energy consumption is reduced.

Cooling System

Structural Support: Using geothermal mesh in the concrete structure of the cooling system can provide additional support. It enhances the durability and compressive strength of concrete, helps maintain the long-term stability of the cooling system, and avoids structural damage caused by temperature fluctuations during the cooling process.

Geothermal Wells

Enhance the Well Wall Structure: In the concrete structure used in geothermal wells, geothermal mesh provides the necessary reinforcement to prevent the well wall from deforming or collapsing in high temperature and high humidity environments, ensuring the long-term stability and reliability of the well wall.

Geothermal Mesh Professional Advantages

High Strength and Durability: Made of high-quality steel wire, it provides superb tensile strength and durability.

Corrosion and High Temperature Resistance: Adapts to extreme environments, prevents corrosion and performance degradation under high temperatures.

Improve Structural Stability: Effectively prevent concrete cracks and enhance structural safety.

Optimize Heat Transfer: Improve the overall heat exchange efficiency of the geothermal system and reduce energy consumption.