Today, High-quality Reinforcement Mesh Supplier will introduce the

construction technology of tunnel reinforcement mesh.

Construction process:

1) Cross-section detection: the inspection of the cross-section and

under-excavation of the cross-section, and timely treatment if the requirements

are not met.

2) Initial sprayed concrete: After the section meets the requirements,

initial sprayed concrete should be carried out.

3) Anchor driving: Anchor driving shall be performed after the strength of

the first shot concrete meets the requirements.

4) Reinforcement mesh installation: After the anchor rod installation is

qualified, the reinforcement mesh installation should be performed, and the

position of the reinforcement mesh should meet the design requirements.

5) Shotcrete: Shotcrete construction on the reinforced mesh after the

reinforcement mesh installation inspection is qualified.

Reinforcement mesh construction process flow chart:

1. Before using the steel bar, remove the rust.

2. When the finished reinforced mesh is installed, its overlap length is not

less than 200mm. The reinforced mesh should be laid after spraying a layer of

concrete on the rock surface; when a double-layer reinforced mesh is used, the

second layer of reinforced mesh should be laid after the reinforced mesh is

covered by concrete.

3. The steel mesh should be firmly connected to the anchor rod, steel arch or

other anchoring device, and the steel mesh should not shake during spraying.

4. Before spraying concrete, hang the steel mesh on the rock surface.

5. Reinforced mesh should usually be arranged in the ring and longitudinal

directions.

6 Reinforced mesh should be laid according to the actual overlying shape of

the surrounding rock surface.

7. In order to facilitate the installation of hanging nets, the reinforced

mesh is often processed into mesh pieces first, and the length and width can be

100-200cm.

8. The steel mesh should be firmly connected to the anchor rod or anchor

head, and should be connected as many points as possible to reduce the "string

vibration" of the mesh reinforcement when spraying the concrete. The anchoring

depth of the anchor shall not be less than 20cm. To ensure that the connection

is strong, safe and reliable.

9. When spraying is started, the distance from the spray head to the sprayed

surface should be appropriately shortened, and the spraying angle should be

appropriately adjusted to make the concrete on the back of the steel mesh dense.

For dry soil tunnels, the spray must not be too thick, otherwise the concrete

will bulge or peel.

10. In the sand layer area, pay attention to laying the fine steel mesh close

to the sand layer, and then spraying the concrete. Before the formal spraying,

spray a layer of cement mortar with an increased amount of accelerator, and

reduce the working wind pressure of the sprayer appropriately.

11. In areas with water, the mix ratio should be changed to increase the

amount of cement. First spray the mixture dry, and after gradually mixing with

the gushing water, gradually add water to spray. When spraying, from near to

far, approach the gushing point gradually, then install a duct at the gushing

point to lead the water out, and then spray near the duct.

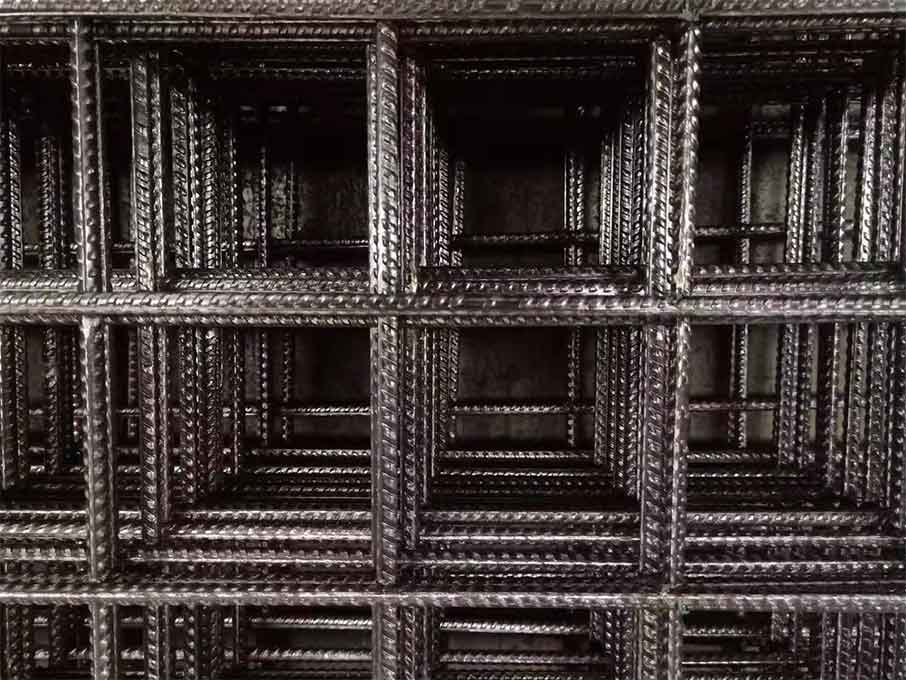

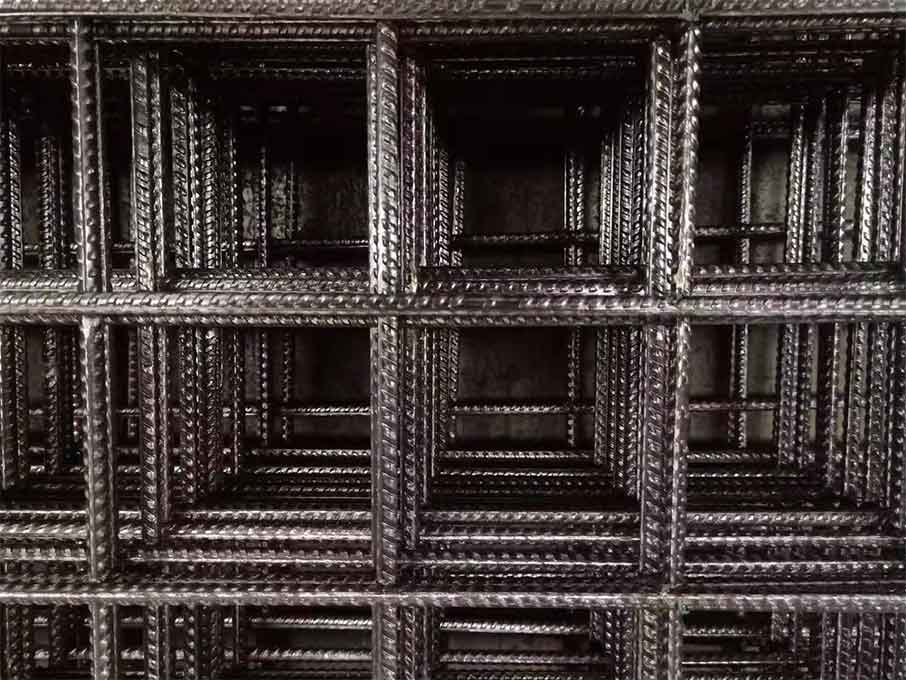

Rebar Mesh

Precautions

1. Rebar Mesh needs to be derusted before use, and made separately outside

the hole.

2. The reinforced mesh is laid 4cm after the initial sprayed concrete to form

a whole with the sprayed concrete, and the thickness of the sprayed concrete

protective layer should not be less than 3cm.

3. Reinforced mesh should be laid on the sandy soil section first, and then

compressed in the circumferential direction before spraying concrete.

4. When double-layer reinforced mesh is used, the second layer of reinforced

mesh should be laid after the reinforced mesh is covered with concrete, and its

covering thickness should not be less than 3cm.

5. The steel mesh should be close to the rock surface. The steel mesh should

be firmly connected with the anchor rod or other fixing devices. When binding

with the steel frame, it should be tied to the side near the rock surface.

6. When spraying concrete, the distance between the spray head and the

sprayed surface and the spray angle should be adjusted to reduce the vibration

of the steel bar, reduce the rebound, and ensure that the thickness of the steel

mesh sprayed concrete protective layer is not less than 20mm.

7. If any falling stone or concrete block is caught by the reinforcement mesh

during spraying, it should be removed in time before spraying the concrete.