Reinforcement Mesh is a new type of high-efficiency, energy-saving, reinforced concrete structure for building materials. It is widely used in airport runways, highways, tunnels, concrete pipes, bridges, multi-story and high-rise buildings, hydraulic dam foundations, docks, warehouses, and sewage treatment tanks Concrete structure. It has the advantages of improving structural strength, saving steel, saving labor, convenient transportation, fast construction, high grid arrangement scale accuracy, easy specialization, large-scale production, and comprehensive cost-effectiveness.

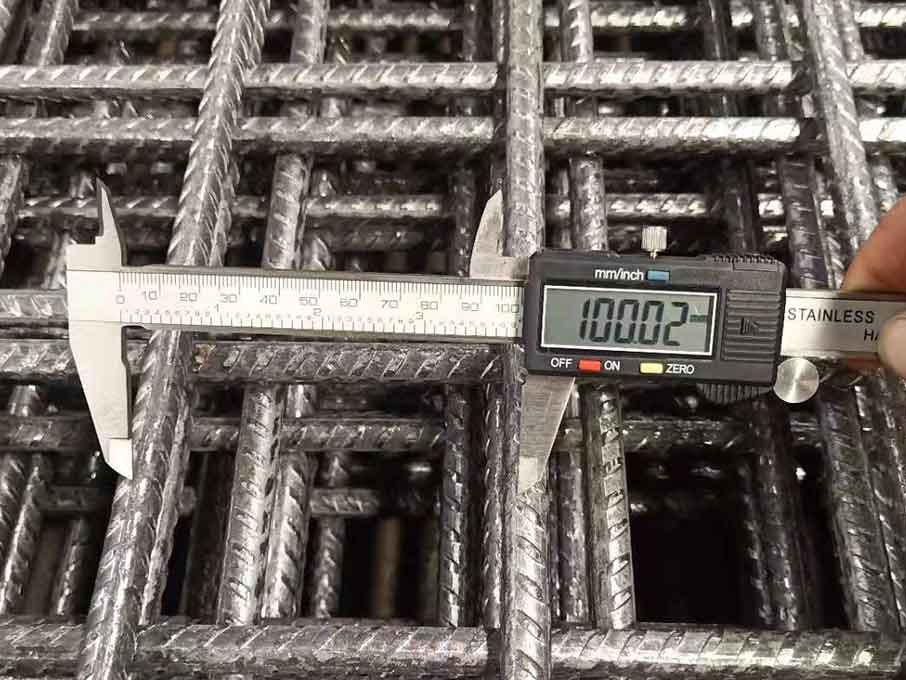

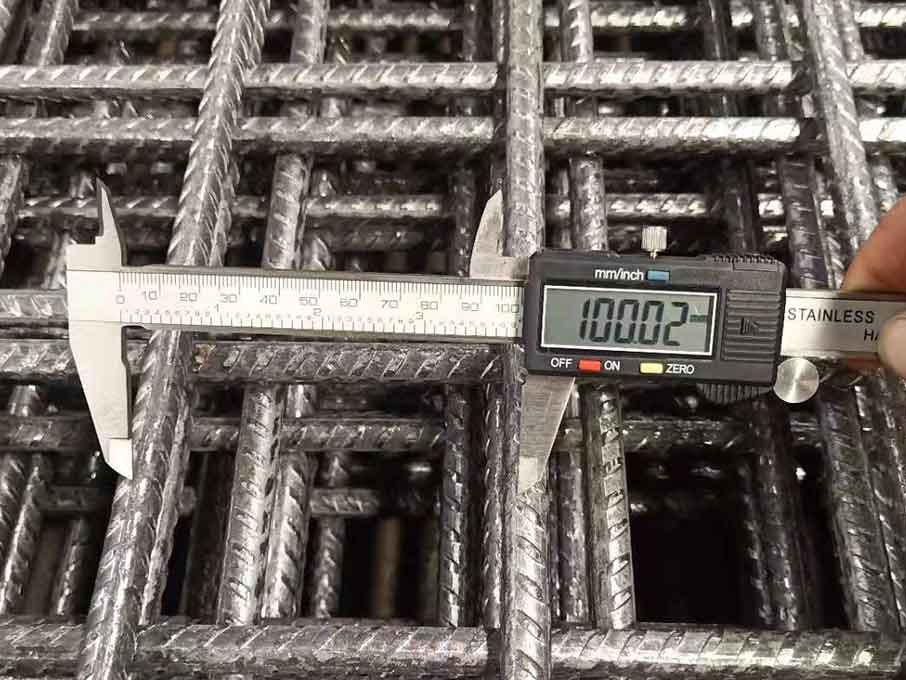

The minimum diameter and spacing of the reinforcement mesh of reinforced concrete pavement should comply with current industry standards. When selecting cold-rolled ribbed reinforcement, the diameter of the reinforcement should not be less than 8mm, and the same diameter should be used for the longitudinal and transverse reinforcement of Rebar Welded Wire Mesh. The thickness of the reinforcing steel protective layer is not less than 50mm.

Rebar Welded Wire Mesh

When the expansion joint of the concrete pavement is connected to the fixed structure, a double-layer steel mesh can be set at the end of the adjacent structure, or the thickness of the plate can be gradually increased on the basis of 20%. The connection range between the concrete pavement and the bridge is about 6 times and 10 times the thickness. When there is a rider at the bridgehead, the stencil manufacturer pointed out that the sheet should be placed in the rider board. A reinforced concrete surface transition board with a length of 610 mm is provided between the concrete surface and the slab. When the bridge is inclined, the sharp corners of reinforced concrete slabs shall be reinforced with a reinforced grid.

Under the concrete surface, the box structure is cut horizontally, and the distance between the top surface and the bottom is less than 400mm or embedded in the bottom layer. On the upper width and sides of the structure, a double-layer steel mesh is set on the concrete surface, the upper and lower surfaces of the upper and lower reinforcing meshes, and the lower surface of 1/3 thickness.

Below the concrete surface, there are circular tubular structures that cross horizontally. The gap between the surface and the bottom is less than 1200mm. On both sides of the structure, a single layer of steel mesh should be set on the concrete surface, and the steel mesh is located at 1/4/3 of the thickness of the surface layer. The application of steel mesh in bridge engineering is mainly used for the deck pavement of municipal bridges and highway bridges, the renovation of old bridges and the prevention of cracks in piers. Through the quality inspection of thousands of domestic bridges, the deck pavement quality has been significantly improved.

For the use of reinforced mesh in highway cement concrete pavement engineering, when Welded Mesh With Ribbed is selected, the diameter of the reinforcing bars should not be less than 8mm, the spacing of the longitudinal reinforcing bars should not be greater than 200mm, and the spacing of the transverse reinforcing bars should not be greater than 300mm. The longitudinal and transverse reinforcement of the welded mesh should be the same diameter, and the thickness of the protective layer of the reinforcement should not be less than 50mm. The welded mesh for reinforcement of the reinforced concrete pavement can be implemented in accordance with the relevant regulations of the welded mesh for reinforced concrete pavement. Under the concrete surface layer, there is a circular tubular structure crossing horizontally. When the distance from the top surface to the bottom surface of the surface layer is less than 1200mm, a single layer of reinforced mesh should be arranged in the concrete surface layer on both sides of the structure. 1/4 to 1/3 thickness.